September 2025

Image taken by long-armed Paul Nazarets from DECA Windows. Left to Right: Paul, Andrew, JJ, and Anita

Greetings from Graphite!

Here in Amherst, we’re in the tail end of summer as the students are slowly rolling into town, and the whole town is bustling again with new faces and fresh energy. As the seasons begin their shift, many of us are packing away our summer clothes and bringing those trusty sweaters and hoodies out of storage (even if we know a few warm days are left ahead).

It’s also the perfect time to turn our attention to our homes and begin swapping out filters, prepping for falling leaves, and giving our gardens a good pruning before the first frost. But as we look ahead toward autumn and winter, now’s also a moment to consider: Is the insulation in our homes up to the challenge? Are there drafty spots that could use attention? Are ready to switch to heat pumps?

At Graphite Studio we love helping our clients work through the best ways to keep homes comfy, resilient, and healthy for the colder months ahead. Learning about innovative materials like Glavel or exploring enduring techniques such as Shou Sugi Ban can help make our homes not just beautiful, but also efficient and long-lasting. If you have questions or want to discuss options, please reach out—we’re always happy to help share what we’ve learned.

Here’s to a cozy and creative fall,

Andrew and the Graphite Team!

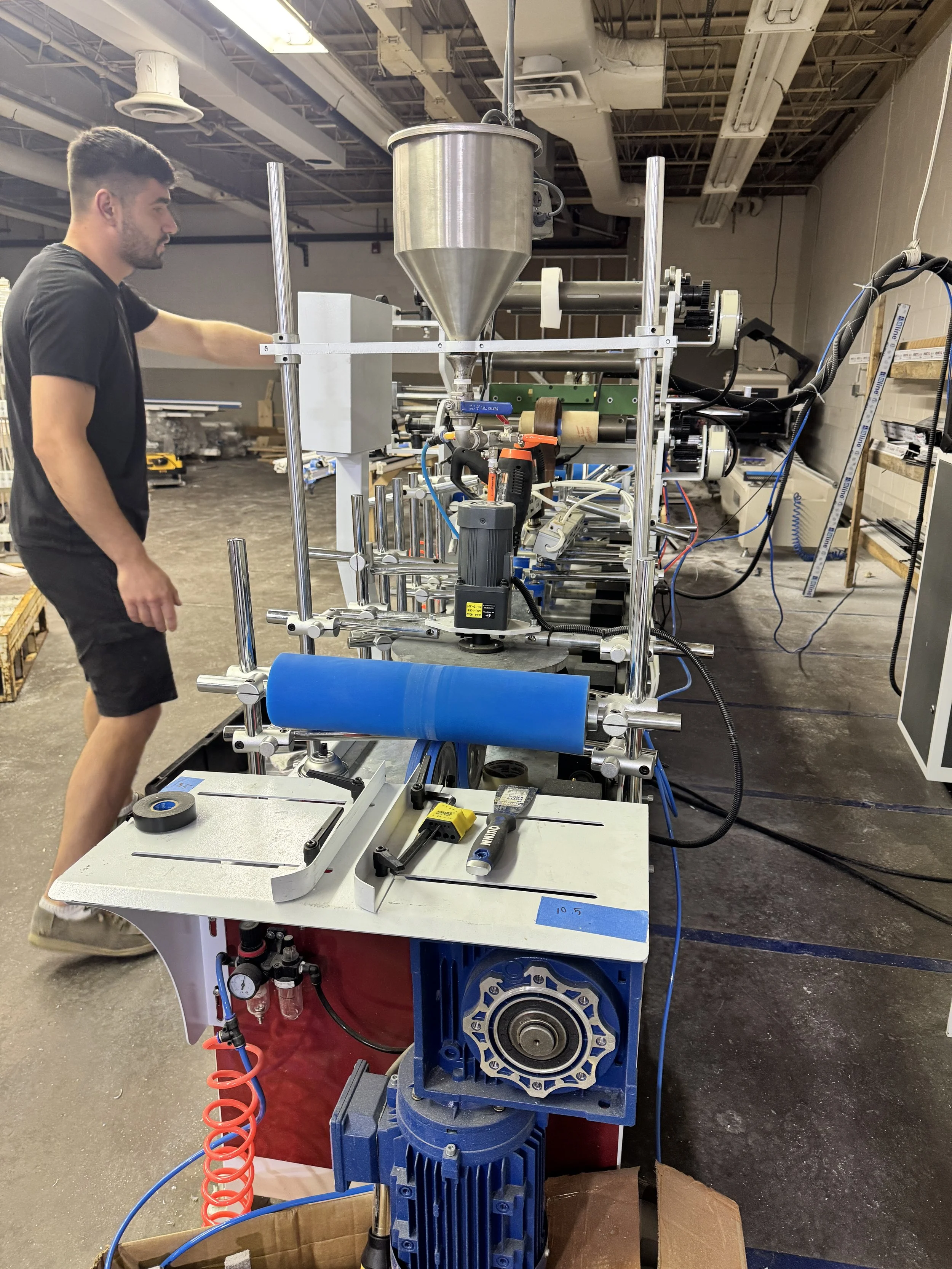

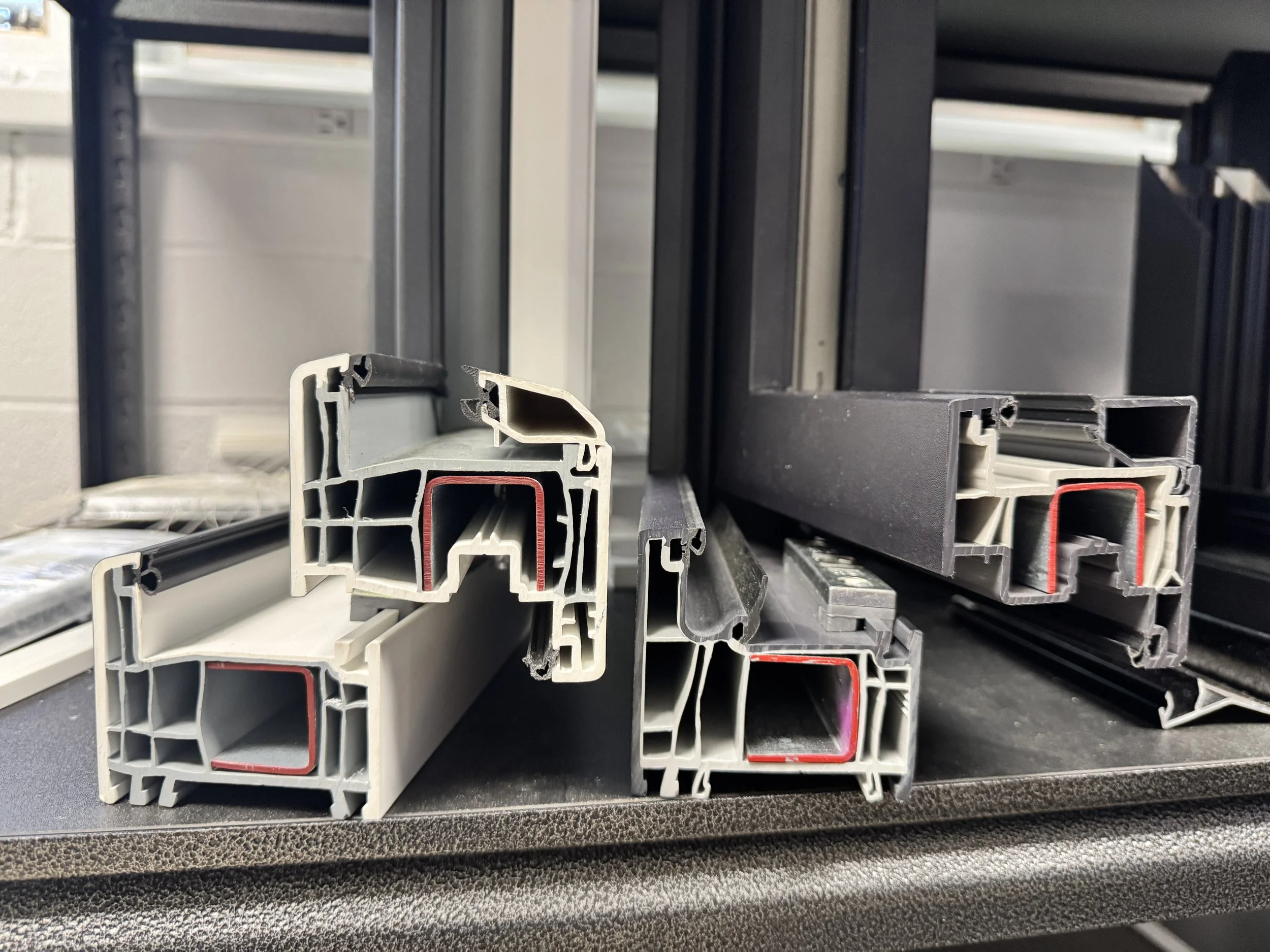

Graphite On The Road: DECA Window Factory Tour

Our recent visit to the Deca Window factory in Westfield, MA was a refreshing look at how European-style windows and doors are being tailored for New England right here in our backyard. Deca’s tilt-and-turn windows, with their simple operation, triple pane options, and up to eleven locking points, immediately stood out for their practical benefits. While we admired their range of high-tech sliders, like the PSK Parallel Slide and Lift & Slide, systems capable of spanning impressive openings caught our attention.

It was also clear that attention to things like lead times (just four to six weeks for custom orders!), rigorous performance testing, and numerous gaskets distinguishes Deca’s approach. But as with any specialized system, builders and designers will want to coordinate early on the sequencing, thresholds, and hardware during project planning. Knowing these finer points helps keep installation frustration at bay and ensures that these locally built, high-performance windows and doors look and function their best for years to come.

Our friends at Birchmore Builders are prepping to install their second round of these new-to-us windows.

Project Progress: Wedgewood

We’ve begun another partnership with a design/build firm - working with Byggmeister out of Newton, MA, to pinch hit as in-house design support for their busy team.

Working alongside the design-build team at Byggmeister has been a delight for us at Graphite Studio.

Byggmeister, with their deep experience in renovation and remodeling, brings their own processes and habits, their practically-trademarked names for each step and milestone, and a company well trained in delivering projects to clients with great satisfaction.

We’re always taking notes when we work with other shops - to see what processes we might crib from, what we can modify to suit our workflows, and what we can share from our background and client base that might help others grow.

For us, collaborating in this environment underscored how transparency, communication, and cross-disciplinary insight can enrich the creative process and deliver homes that truly serve clients over the long term. We’re always in search of a new design/build partnership where we can learn from both builders and designers.

Graphite Science: Glavel

What looks like lava rocks, could sand the callouses off your hands, but also helps us avoid foam and concrete in green building projects? Glavel! Glavel is a foam glass product made in Vermont from recycled glass. Unlike a conventional system which separates insulation from structure and drainage, Glavel’s approach is inherently multifunctional. The foundation assembly begins with a full foot of compacted Glavel, which on its own delivers R-20 insulation, covered by a non-woven geotextile.

In the detail above, we’re borrowing wisdom from Steve Demetrick’s “slabless slab” strategy, to create a basement floor system without concrete. Over the Glavel, we add a layer of compacted and screed pea stone to ensure stability and proper drainage. Instead of traditional concrete, two criss-crossed, screwed and glued layers of Advantech provide stable footing in this basement.

What makes Glavel particularly attractive for forward-thinking builders is its environmental benefits. Unlike foam board, Glavel is Red List Free, which means its composition steers clear of the chemicals prohibited by the Living Building Challenge and other progressive green building standards. In fact, using Glavel can reduce the overall embodied carbon of a foundation by as much as tenfold compared to typical foam- and concrete-based methods, all while simplifying installation and sequencing on site.

The future of sustainable, high-performance building is unfolding from the ground up—with fewer layers, a lighter footprint, and smarter material choices that benefit both homes and the planet we share. If you or your clients are aiming for next-level sustainability, it’s time to rethink what’s under your feet.

(full disclosure: we’re drawing an updated set of details for the folks at Glavel, based on feedback they’ve received from right-thinking designers and builders in the field)

Graphite Science: Shou Sugi Ban

(Image by https://pioneermillworks.com/blog/history-of-shou-sugi-ban-yakisugi)

Shou Sugi Ban, the centuries-old Japanese technique of charring wood, immediately captured our attention at Graphite Studio for its poetic blend of beauty and resilience. We’d used it only once, here in Amherst, but thought it was time to deepen our knowledge.

A few weeks ago, we attended Pioneer Millworks’ webinar exploring this craft, which showcased the remarkable versatility and thoughtful execution professionals can achieve when tradition meets modern building needs. (Pioneer Millworks is another company in our Building Energy Bottom Lines network!)

Specifying Shou Sugi Ban is more than selecting a distinctive finish; it’s embracing the philosophy that beauty can cooperate with performance. Charring brings out dramatic relief in the wood grain, letting each board develop its own patina over time. This timeless aesthetic lends warmth and sophistication to both modern and rustic façades.

The process itself transforms wood through thermal modification. By carefully burning just the outward face, cellulose and lignin are carbonized, forming a protective barrier against moisture, insects, fire, and UV degradation. Pioneer Millworks applies this technique using sustainably harvested woods such as Larch and Douglas fir, milled in custom chambers to ensure consistency and depth of finish. The catalog offers options ranging from “Deep Char” with tactile, alligator-like texture to brushed profiles that expose swirling grain and multidimensional hues. Proper installation and occasional oiling often suffice for maintenance, letting the finish evolve gracefully without synthetic preservatives. By sourcing responsibly and relying on fire instead of chemicals, Pioneer Millworks minimizes environmental impact and the carbon footprint—all while curating finishes that delight and endure for decades.